Views: 0 Author: Site Editor Publish Time: 2025-10-02 Origin: Site

Test pumps play a critical role in maintaining the safety and efficiency of pipelines, plumbing systems, HVAC setups, and industrial equipment. They are used to pressurize systems, detect leaks, and verify performance before full operation. However, improper operation can lead to accidents, equipment damage, or inaccurate test results. Ensuring safe handling of a test pump is essential not only for protecting operators but also for preserving the integrity of the system being tested. Understanding proper safety measures, equipment handling, and procedural steps helps operators conduct testing efficiently while minimizing risks. Safe operation practices are especially important when dealing with high-pressure systems, hazardous fluids, or complex industrial installations.

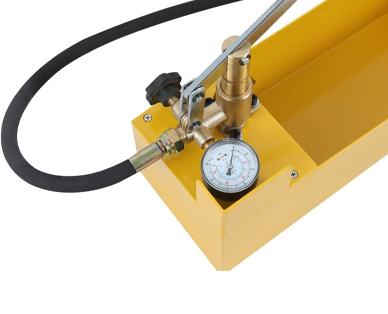

A test pump is a specialized device designed to pressurize pipelines, plumbing systems, and industrial equipment to check for leaks, verify system performance, and ensure operational reliability. It provides an accurate simulation of working conditions, allowing operators to detect weaknesses or faults before full-scale use.

Manual Test Pumps: Hand-operated pumps ideal for small systems or portable applications. They are simple to use and require minimal setup.

Electric Test Pumps: Motor-driven pumps that provide higher pressure capabilities for industrial and commercial systems. They allow for faster and more consistent testing.

Hydraulic Test Pumps: Suitable for high-pressure pipelines and heavy-duty industrial equipment, offering precise control and reliability.

Pneumatic Test Pumps: Air-operated pumps used for both liquid and gas systems, particularly useful where electrical power is limited or hazardous environments exist.

Pressure Testing: Ensures pipelines and equipment can withstand operating pressures safely.

Leak Detection: Identifies weak points or faulty seals to prevent future system failures.

System Diagnostics: Helps troubleshoot performance issues, verify installation quality, and maintain compliance with industry standards.

Understanding the types, purposes, and applications of test pumps is crucial for safe and effective operation in any setting.

Operating a test pump safely begins with thorough preparation and awareness of potential hazards. Following proper safety precautions helps prevent accidents, equipment damage, and inaccurate test results.

Always wear appropriate PPE, including gloves, safety goggles, and protective clothing, to protect against fluid leaks, high pressure, and accidental splashes.

For chemical or hazardous fluid systems, additional protective gear may be required, such as face shields or respirators.

Ensure the system is fully depressurized before connecting the test pump.

Disconnect from live electrical sources or active flows to avoid shocks, unexpected starts, or fluid surges.

Check that all valves, fittings, hoses, and connectors are intact and free from damage, corrosion, or wear.

Replace any compromised components to prevent leaks or bursts during testing.

Read and follow the manufacturer’s instructions and safety guidelines for the specific test pump being used.

Verify maximum allowable pressures, compatible fluids, and recommended operating procedures to ensure safe and accurate testing.

Adhering to these precautions sets the foundation for a safe, efficient, and reliable test pump operation.

Operating a test pump safely is critical to ensure accurate system testing, prevent equipment damage, and protect personnel. By following a structured procedure, operators can achieve reliable results while maintaining high safety standards. Below is a comprehensive guide for safe test pump operation:

Begin by carefully connecting the test pump to the system using the correct fittings, hoses, and adapters.

Verify that all connections are secure and leak-free to prevent accidental fluid discharge or detachment under pressure.

For complex systems, label connections and ensure valves are properly positioned to avoid cross-contamination or system errors.

Many test pumps require priming with the appropriate fluid, such as water or oil, depending on system specifications.

Proper priming removes air pockets that can lead to inaccurate readings, cavitation, or pressure fluctuations.

Ensure that the fluid is clean and free from debris to protect the pump and system components during testing.

Slowly increase the pressure using the pump, monitoring gauges to ensure the system does not exceed safe operational limits.

Avoid sudden surges in pressure, which can damage pipes, seals, or sensitive equipment.

Use a stepwise approach, allowing the system to stabilize at intermediate pressures before reaching the test level.

Observe the system throughout the test, checking pressure levels, flow consistency, and any signs of leakage.

Listen for unusual noises, vibrations, or other indicators of potential issues.

Document readings for each stage to support maintenance records and troubleshooting.

If abnormalities appear, immediately stop the test to prevent further damage or safety hazards.

After completing the test, release pressure gradually according to manufacturer instructions.

Use relief valves if available and ensure personnel remain clear of high-pressure outlets.

Sudden depressurization can lead to fluid sprays or damage to system components, so careful control is essential.

Carefully disconnect the pump from the system, taking care not to spill fluids or damage fittings.

Inspect the test pump, hoses, valves, and connections for signs of wear, leaks, or damage.

Perform necessary maintenance, cleaning, or replacement of worn parts to ensure readiness for future tests.

Operating a test pump without proper precautions can lead to inaccurate results, equipment damage, or safety hazards. Awareness of common mistakes helps operators maintain safety and efficiency:

Applying pressure beyond the system’s specifications can cause pipe bursts, seal failure, or component damage.

Always check system ratings and gradually increase pressure to avoid overloading.

Worn, cracked, or mismatched hoses can leak or detach under pressure, posing safety risks.

Inspect all hoses, valves, and adapters before use, and replace any defective components.

Every test pump has maximum pressure, fluid type, and flow specifications.

Exceeding these limits may damage the pump or affect test accuracy. Always adhere to manufacturer guidelines.

Testing without gloves, goggles, or protective clothing increases the risk of fluid exposure or injury.

Proper PPE ensures operator safety during pressurization and fluid handling.

Proper care and storage prolong the life of a test pump and maintain reliable performance:

Rinse and clean the pump and hoses to remove residues, debris, or corrosive fluids.

Prevents contamination and ensures accurate readings during future tests.

Check for leaks, cracks, worn seals, or damaged components before and after each use.

Replace any faulty parts promptly to maintain safe operation.

Store the test pump in a dry, secure location to protect against moisture, dust, or accidental impacts.

Proper storage prevents corrosion, mechanical damage, and ensures readiness for future testing.

Safe operation of a test pump is essential to achieve accurate results, protect personnel, and prevent equipment damage. By avoiding common mistakes such as over-pressurizing or using faulty components, and following proper maintenance and storage practices, operators can ensure long-term reliability. Adhering to manufacturer guidelines and wearing appropriate PPE further enhances safety.

For businesses and maintenance professionals seeking dependable solutions, consulting professional suppliers like Jiangsu Bohui Co., Ltd. is highly recommended. Expert suppliers provide guidance on pump selection, safe operation, and maintenance best practices, ensuring efficient and secure pump testing for residential, commercial, and industrial applications.