Views: 0 Author: Site Editor Publish Time: 2025-09-23 Origin: Site

A test pump is an essential tool used to evaluate the performance and integrity of various fluid systems. From small residential plumbing to complex industrial pipelines, test pumps play a critical role in ensuring that installations are leak-free, safe, and functioning at the required pressure levels.

Understanding what a test pump does is vital for maintenance teams, contractors, and engineers. Proper use of a test pump helps identify potential weak points, detect leaks, and verify that systems can operate under pressure without failure. By providing accurate and controlled pressurization, test pumps not only improve system safety but also enhance operational efficiency, prevent costly repairs, and extend the lifespan of pipelines and equipment.

Whether in heating, compressed air, refrigeration, oil installations, or sprinkler systems, a test pump ensures that both new and existing systems meet quality and safety standards, making it an indispensable device in industrial, commercial, and even residential settings.

A test pump is a specialized device designed to measure pressure, flow, and the overall integrity of pipelines and equipment. By generating controlled pressure within a system, it allows technicians and engineers to evaluate whether a pipeline or installation can withstand operational demands without leaks or failures.

Test pumps come in various types, including manual hand pumps, electric pumps, and pneumatic or hydraulic models, each suited for different pressure ranges and system sizes. They typically consist of a pump body, valves, pressure gauges, and hoses, enabling precise control and monitoring during testing.

Plumbing: Testing water pipes, connections, and faucets for leaks before commissioning.

HVAC systems: Ensuring heating, cooling, and air-conditioning systems maintain proper pressure.

Chemical and industrial pipelines: Checking for integrity and safety in transporting liquids or gases.

Water supply systems: Inspecting small-bore and large-scale water networks for leaks or pressure drops.

By providing reliable performance data, a test pump is an essential tool for maintaining safety, operational efficiency, and compliance across residential, commercial, and industrial systems.

A test pump operates on the simple yet effective principle of pressurizing a system to evaluate its performance, integrity, and leak resistance. By introducing a controlled pressure—either with liquid, air, or hydraulic fluid—the pump allows technicians to simulate real operating conditions and detect any weaknesses or potential failures in pipelines, tanks, or equipment.

Pressurization: The pump forces fluid or gas into the system, raising the internal pressure to a predetermined level.

Monitoring: Pressure gauges or sensors track the system pressure to ensure it reaches and maintains the target value.

Leak Detection: Any drop in pressure or visible leakage indicates a potential fault or weak point.

Verification: Once the system holds the pressure without loss, it confirms integrity and readiness for operation.

Water Test Pumps: Common for plumbing, heating, sprinkler, and small-bore pipe systems. Water acts as the working fluid to test leaks and pressure performance.

Air or Gas Test Pumps: Used in systems where water cannot be applied, such as compressed air pipelines or gas installations. Safety precautions are critical due to the compressibility of gases.

Hydraulic Test Pumps: Employ hydraulic fluid to generate higher pressures, suitable for industrial pipelines, chemical installations, and other high-pressure applications.

Understanding the working principle and type selection ensures that the test pump delivers accurate, safe, and reliable results, making it an indispensable tool for system commissioning, maintenance, and troubleshooting.

Test pumps come in various designs, each tailored for specific applications, system sizes, and pressure requirements. Choosing the right type is crucial for accurate testing, safety, and efficiency.

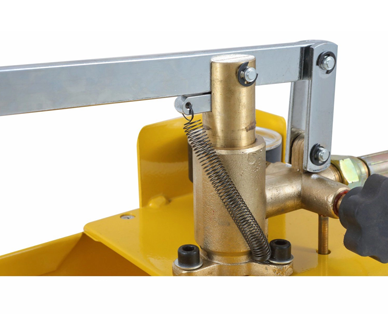

Operation: Hand-operated pumps that pressurize small to medium systems.

Applications: Ideal for plumbing, small-bore pipe installations, and portable testing.

Advantages: Compact, easy to transport, low maintenance, and suitable for on-site troubleshooting.

Example Features: Some models feature a plastic tank with a brass pump body for long-term durability, while others use steel tanks and aluminum bodies for easy handling.

Operation: Motor-driven pumps capable of generating higher pressures automatically.

Applications: Industrial pipelines, heating systems, and large-scale water or chemical networks.

Advantages: Faster testing, consistent pressure output, and reduced manual effort.

Operation: Use hydraulic fluid to produce very high pressures.

Applications: High-pressure pipelines, pressure vessels, and chemical installations.

Advantages: Can handle demanding industrial testing conditions and ensure precise pressure control.

Operation: Air-operated pumps designed for both liquid and gas systems.

Applications: Compressed air pipelines, gas installations, and pressurized systems where liquids cannot be used.

Advantages: Safe for certain applications, adaptable for both industrial and commercial systems, and capable of continuous operation.

By understanding the differences between these test pump types, users can select the most suitable pump for their specific system requirements, ensuring reliable pressure testing, leak detection, and overall system integrity.

Test pumps are versatile tools widely used across residential, commercial, and industrial sectors. Their ability to simulate operational pressures and detect leaks makes them essential for ensuring system reliability and safety.

Purpose: Confirm the integrity of water, oil, or chemical pipelines before commissioning.

Process: Pressurize the system using a manual, electric, or hydraulic test pump and monitor for any pressure drops.

Benefits: Identifies weak points, prevents future leaks, and reduces costly repairs.

Purpose: Ensure heating, ventilation, air-conditioning, and plumbing systems are operational and leak-free.

Application: Test pumps pressurize water or air lines to verify performance and detect potential failures.

Benefits: Guarantees system efficiency, extends equipment lifespan, and ensures occupant comfort and safety.

Purpose: Test the operational readiness of pumps, tanks, and other industrial equipment.

Application: Hydraulic or electric test pumps are used to simulate working conditions and assess equipment tolerance to pressure.

Benefits: Ensures compliance with industry standards and prevents operational downtime.

Purpose: Verify that fire protection systems and water supply lines maintain proper pressure.

Application: Manual or electric test pumps pressurize sprinkler networks and storage tanks for safety checks.

Benefits: Protects property and lives by ensuring fire systems are reliable and functional.

By using a test pump in these applications, professionals can ensure system integrity, improve safety standards, and reduce maintenance costs, making it a critical tool in construction, maintenance, and industrial operations.

Using a test pump offers numerous benefits for both industrial and commercial applications. By pressurizing systems and evaluating their integrity, test pumps help ensure safety, efficiency, and reliability.

Function: Confirms that water, air, or chemical pipelines and equipment can withstand operational pressures.

Benefit: Prevents system failures that could cause accidents, environmental hazards, or costly downtime.

Function: Pressurizes systems to reveal potential leaks, cracks, or weak points in pipelines, valves, and joints.

Benefit: Early detection helps avoid major failures and ensures that systems perform optimally from the start.

Function: Provides quick and precise testing without the need for trial-and-error repairs.

Benefit: Reduces maintenance time and prevents expensive replacements or emergency repairs.

Function: Supports verification of system pressure and integrity according to local regulations and industrial standards.

Benefit: Ensures legal compliance and quality assurance for residential, commercial, and industrial installations.

By integrating a test pump into regular system checks, engineers, maintenance teams, and contractors can maintain safer, more efficient, and longer-lasting pipelines and equipment, while also reducing costs and ensuring compliance with industry regulations.

A test pump is an essential tool for maintaining the safety, reliability, and efficiency of pipelines, HVAC systems, industrial equipment, and water networks. By pressurizing systems and identifying leaks or weaknesses, it prevents operational failures, reduces maintenance costs, and ensures consistent performance across industries.

Selecting the right type of test pump—manual, electric, hydraulic, or pneumatic—is crucial to match specific system requirements and application needs. The proper pump guarantees accurate testing, long-term durability, and safe operation.

For businesses and professionals seeking high-quality and reliable test pump solutions, consulting a reputable supplier is highly recommended. Jiangsu Bohui Co., Ltd. offers expert guidance on pump selection, operation, and maintenance, helping ensure systems are tested efficiently, safely, and effectively. By working with experienced suppliers, companies can achieve optimal testing results while protecting their pipelines, equipment, and overall investment.